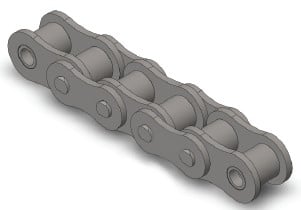

Roller chains are one of the most effective and cost eff ective ways to transmit mechanical energy in between shafts. They operate in excess of a wide variety of speeds, manage big operating loads, have incredibly little power losses and are normally reasonably priced compared with other solutions

of transmitting power. Successful choice involves following many fairly straightforward methods involving algebraic calculation as well as the utilization of horsepower and service aspect tables.

For just about any offered set of drive ailments, there are a number of possible chain/sprocket confi gurations that could effectively operate. The designer consequently needs to be mindful of quite a few primary choice principles that when applied properly, assist balance overall drive overall performance and expense. By following the steps outlined in this segment designers ought to be in a position to make choices that meet the requirements with the drive and therefore are price eff ective.

General Roller Chain Drive Rules

? The advised number of teeth for your modest sprocket is 15. The minimum is 9 teeth – smoother operation is obtained with much more teeth.

? The recommended maximum variety of teeth to the significant sprocket is 120. Note that even though extra  teeth makes it possible for for smoother operation owning too a lot of teeth leads to chain jumping off the sprocket following a relatively modest quantity of chain elongation as a consequence of put on – That is definitely chains which has a incredibly large quantity of teeth accommodate much less dress in in advance of the chain will no longer wrap around them effectively.

teeth makes it possible for for smoother operation owning too a lot of teeth leads to chain jumping off the sprocket following a relatively modest quantity of chain elongation as a consequence of put on – That is definitely chains which has a incredibly large quantity of teeth accommodate much less dress in in advance of the chain will no longer wrap around them effectively.

? Speed ratios should be seven:one or much less (optimum) rather than greater

than 10:1. For greater ratios the usage of a number of chain reductions is recommended.

? The advisable minimum wrap from the tiny sprocket is 120°.

? The proposed center distance among shafts is 30-50 pitches of chain. There are two exceptions to this as follows:

1. The center distance have to be higher than the sum of your outside diameters of the driver and driven sprockets to avoid interference.

two. For pace ratios better than three:1 the center distance shouldn’t be significantly less compared to the outdoors diameter in the large sprocket minus the outdoors diameter of the little sprocket to assure a minimal 120° wrap about the modest sprocket.

ASME/ANSI Drive Chain

Tags: